Schadahtech Welding Supplies Limited

Welding Machines

Welding Machines can be grouped into four(4) main types of welding processes namely:

1.) Arc Welding also referred to as Shielded Metal Arc Welding.(SMAW)

Stick welding uses an electric current between the base metal and the stick (filler rod) to generate heat for welding.

SMAW welders are among the most economical welders recommended for steel, inox steel & cast iron. Stick welding is ideal

for open spaces and outdoor use.

Arc welding is best suited for Construction, Large-Scale Repairs & Structural Manufacturing. Arc welds get very very hot,

and can burn out thin material easily, thinner materials which are more suited to the MIG welding processes.

2.) MIG Welding also referred to as Gas Metal Arc Welding.(GMAW)

MIG Welding stands for Metal Inert Gas Welding. It is typically used for large and thick materials. MIG machines use a

consumable wire as an electrode & a filler material, resulting in a faster process & lower production costs.

The MIG Welding is the most commonly used & also the most easily mastered type of welding. Its core applications include

the fusing of mild steel, stainless steel as well as aluminum.

3.) Gas Welding also referred to as Oxy-Acetylene Torch Welding.

Oxy-Acetylene Torch Welding consists of Mixing Oxygen & Acetylene Gas to create a flame capable of melting steel. The gas

torch is commonly used for brazing softer metals such as copper & bronze.

It can also be applied in the welding of delicate

aluminum parts such as refrigeration pipes. The flame is the main component produced at the end of the torch since it melts

the base metal and possible filler to form the weld.

4.) TIG Welding also referred to as Gas Tungsten Arc Welding.(GTAW)

TIG Welding stands for Tungsten Inert Gas Welding. A TIG Welding is best suited for out high-touch work, for example,

sculptures & architectural features.

TIG welds provide superior finish that needs minimal clean up by sanding or grinding.

The machine operator must hold the welding torch in one hand while feeding the filler wire with the other. The process

requires a non-consumable tungsten electrode to produce a weld.

Types Of Weld Machines?

The popular categories of welding machines in our stock line include:

- Arc Welding

- Gas Welding

- Mig Welding

- Tig Welding

Contact

Contact Us

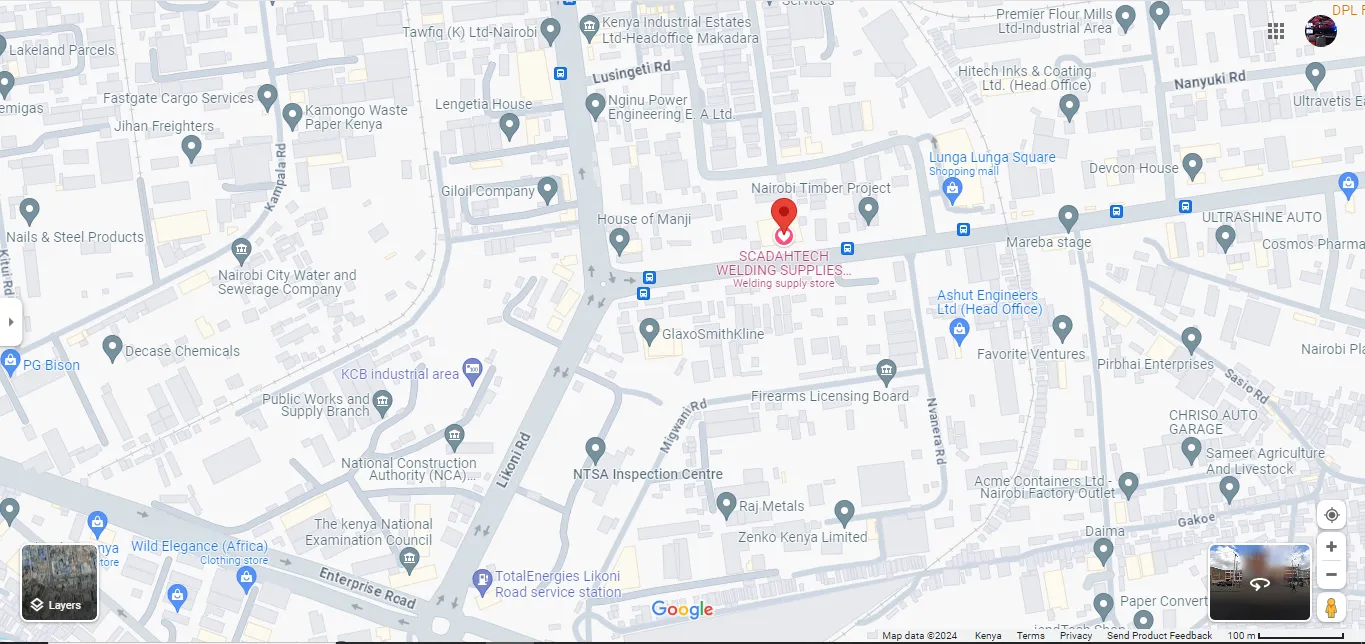

Physical Address

Lunga Lunga Plaza, Lunga Lunga Road, 4th Floor, Room 8. Next To Shell Petrol Station

Email Us

info(@)scadahtechweldingsupplies.com

support(@)scadahtechweldingsupplies.com

Call Us

Land line: 020 2122233

Mobile line: +254 795 340 517

Hot line: +254 100 242 151